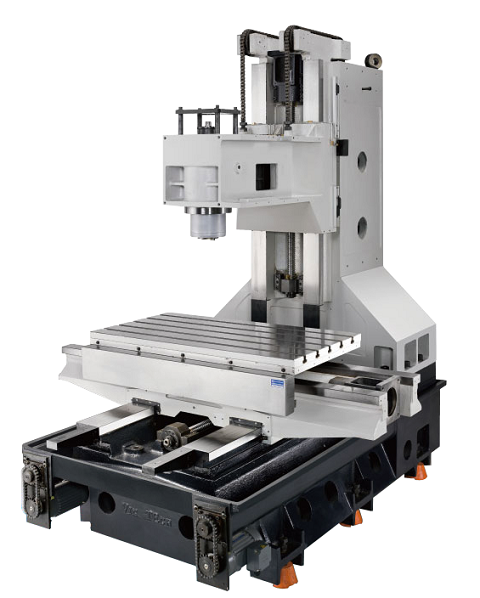

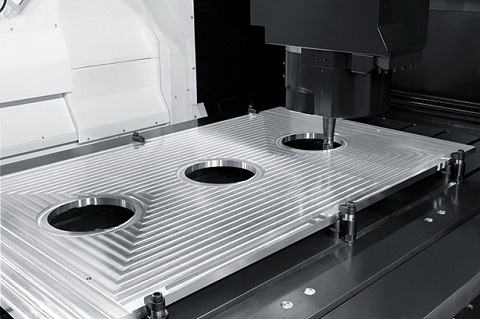

>Widened structure design on machine base and column provides extreme rigidity and durability.

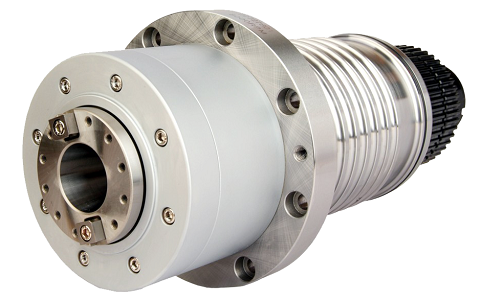

>Direct-drive high speed spindle with fast response, good at rigidly tapping, improve efficiency, reduce tool wear.

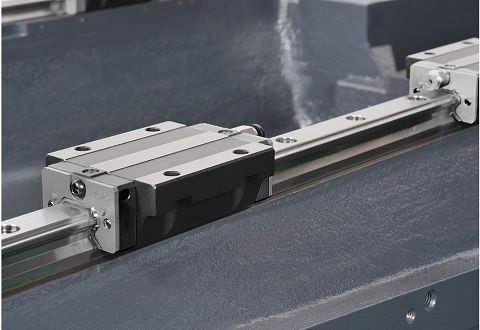

>X, Y, Z-axis with roller/ball linear rolling guide ways, fast travel 48/36m, significantly reducing processing time.

>Without balance weight design on Z-axis, together with brake servo motor, to improve Z-axis* driving performance.

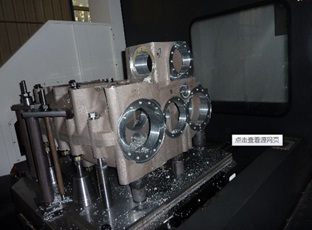

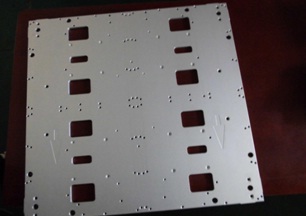

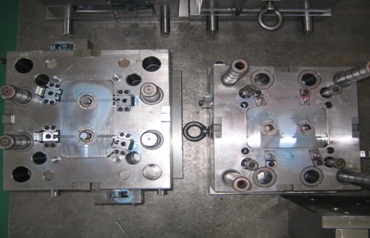

>Suitable for high speed processing of 3C parts and hardware parts.

>12,000rpm or 15,000rpm spindle is configurable.

| Accessories | |

| Standard | Optional |

| 1. Fully enclosed guard | 1. Chip remover device |

| 2. Auto lubrication system | 2. Coolant through spindle(CTS) |

| 3. Pneumatic tool exchange arrangement | 3. Oil-Water separator |

| 4. Blowing device | 4. 4th axis rotary table |

| 5. Coollig arrangement/Lighting arrangement | |

| 6. 3 color light | |

| 7. Adjusting pad block | |

| 8. Spindle coolant arrangement | |

| 9. Air conditioner for electric cabinet | |

| 10. Tool, Toolbox | |

| 11. Technicaldocument | |

| 12. Tools Kit | |