Parameters |

HFC-1810T | HFC-1808H | HFC-1808T | HFC-1812T | HFC-1810H | HFC-1812H | HFC-1206H | HFC-2408H | HFC-1206TNC | HFC-1810TNC | HFC-1812TNC | HFC-1808HNC | HFC-1206T | HFC-1812HNC | HFC-1808TNC | HFC-1808HCNC-17A | HFC-1808TCNC-17A | HFC-1810TCNC-17A | HFC-1810HCNC-17A | HFC-1812HCNC-17A | HFC-1206HCNC-17A | HFC-1206TCNC-17A |

| Grinding Wheel |

Work dia. |

Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ35mm | Φ1~Φ50mm | Φ1~Φ35mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ35mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ50mm | Φ1~Φ35mm | Φ1~Φ35mm |

Special work dia. |

Φ40~Φ100mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ30~Φ60mm | Φ40~Φ120mm | Φ30~Φ60mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ30~Φ60mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ40~Φ100mm | Φ30~Φ60mm | Φ30~Φ60mm |

Dimensions(OD*W*ID) |

Φ455×225×Φ228.6 | Φ455×205×Φ228.6 | Φ455×205×Φ228.6 | Φ455×305×Φ228.6 | Φ455×225×Φ228.6 | Φ455×305×Φ228.6 | Φ305×150×Φ120 | Φ610×205×Φ304.8 | Φ305×150×Φ120 | Φ455×225×Φ228.6 | Φ455×305×Φ228.6 | Φ455×205×Φ228.6 | Φ305×150×Φ120 | Φ455×305×Φ228.6 | Φ455×205×Φ228.6 | Φ455×205×Φ228.6 | Φ455×205×Φ228.6 | Φ455×225×Φ228.6 | Φ455×255×Φ228.6 | Φ455×305×Φ228.6 | Φ305×150×Φ120 | Φ305×150×Φ120 |

Rotative speed |

1520 R.P.M | 1520(600-2000) R.P.M/600 | 1520 R.P.M | 1520 R.P.M | 1520(600-2000) R.P.M/600 | 1520(600-2000) R.P.M/600 | 2000-3000 R.P.M | 900-1500R.P.M | 1950 R.P.M | 1520 R.P.M | 1520 R.P.M | 1520(600-2000) R.P.M | 1950 R.P.M | 1520(600-2000) R.P.M | 1520 R.P.M | 1520(600-2000) R.P.M | 1520 R.P.M | 1520 R.P.M | 1520(600-2000) R.P.M | 1520(600-2000) R.P.M | 1520(1500-2000) R.P.M | 1950 R.P.M |

Drive motor |

15HP(11KW) AC380/50Hz | 15HP(11KW) AC380/50Hz | 15HP(11KW) AC380/50Hz | 20HP(15KW) AC380/50Hz | 15HP(11KW) AC380/50Hz | 20HP(11KW) AC380/50Hz | 10HP(7.5KW) AC380V/50Hz | 30HP(22KW) AC200/50Hz | 7.5HP(5.5KW) AC380V/50Hz | 15HP(11KW) AC380/50Hz | 20HP(15KW) AC380/50Hz | 15HP(11KW) AC380/50Hz | 7.5HP(5.5KW) AC380V/50Hz | 15HP(11KW) AC380/50Hz | 15HP(11KW) AC380/50Hz | 15HP(11KW) AC380/50Hz | 15HP(11KW) AC380/50Hz | 15HP(11KW) AC380/50Hz | 15HP(11KW) AC380/50Hz | 20HP(15KW) AC380/50Hz | 7.5HP(5.5KW) AC380V/50Hz | 7.5HP(5.5KW) AC380V/50Hz |

| Regulation wheel |

Rotative speed |

1-300 R.P.M | 1-300 R.P.M | 1-300 R.P.M | 1-300 R.P.M | 1-300 R.P.M | 1-300 R.P.M | (1-300)R.P.M | 1-300R.P.M | (1-300)R.P.M | 1-300 R.P.M | 1-300 R.P.M | 1-300 R.P.M | (1-300)R.P.M | 1-300 R.P.M | 1-300 R.P.M | 1-300 R.P.M | 1-300 R.P.M | 1-300 R.P.M | 1-300 R.P.M | 1-300 R.P.M | (1-300)R.P.M | (1-300)R.P.M |

Drive motor |

4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 1.3HP(2KW) AC200V/50Hz | 4HP(3KW) AC200/50Hz | 2.6HP(2KW) AC200V/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 2.6HP(2KW) AC200V/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 4HP(3KW) AC220/50Hz | 1.3HP(2KW) AC200V/50Hz | 2.6HP(2KW) AC200V/50Hz |

RW tilt angle |

+6°~-5° | +6°~-5° | +6°~-5° | +6°~-5° | +6°~-5° | +6°~-5° | +5°~-3° | +5°~-3° | +5°~-3° | +6°~-5° | +6°~-5° | +6°~-5° | +5°~-3° | +6°~-5° | +6°~-5° | / | / | +6°~-5° | / | / | +5°~-3° | +5°~-3° |

RW swivel angle |

±6° | ±6° | ±6° | ±6° | ±6° | ±6° | ±5° | ±5° | ±5° | ±6° | ±6° | ±6° | ±5° | ±6° | ±6° | / | / | ±6° | / | / | ±5° | ±5° |

Drive method |

Chain drive | Worm gear speed reducer drive | Chain drive | Chain drive | Worm gear speed reducer drive | Worm gear speed reducer drive | Regulating wheel feeding | Worm gear speed reducer drive | Chain drive | Chain drive | Chain drive | Worm gear speed reducer drive | Chain drive | Worm gear speed reducer drive | Chain drive | Chain drive | Chain drive | Chain drive | Worm gearbox drive | Worm gearbox drive | Worm gearbox drive | Chain drive |

| Spindle |

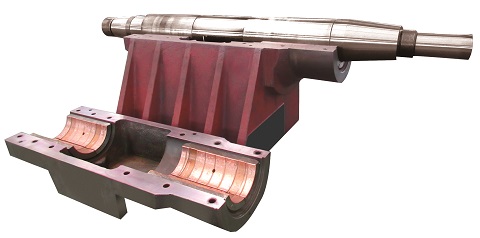

Spindle type |

Hydrodynamic pressure type | Hydrostatic pressure type | Hydrodynamic pressure type | Hydrodynamic pressure type | Hydrostatic pressure type | Hydrostatic pressure type | Hydrostatic pressure type | Hydrodynamic pressure type | Hydrodynamic pressure type | Hydrodynamic pressure type | Hydrodynamic pressure type | Hydrostatic pressure type | Hydrodynamic pressure type | Hydrostatic pressure type | Hydrostatic pressure type | Hydrodynamic pressure type | Hydrodynamic pressure type | Hydrodynamic pressure type | Hydrostatic pressure type | Hydrostatic pressure type | Hydrostatic pressure type | Hydrodynamic pressure type |

Spindle rotative precision |

<0.002mm | <0.0015mm | <0.002mm | <0.002mm | <0.0015mm | <0.0015mm | <0.0015mm | <0.0015mm | <0.002mm | <0.002mm | <0.002mm | <0.0015mm | <0.002mm | <0.0015mm | <0.002mm | <0.0015mm | <0.002mm | <0.002mm | <0.0015mm | <0.0015mm | <0.0015mm | <0.002mm |

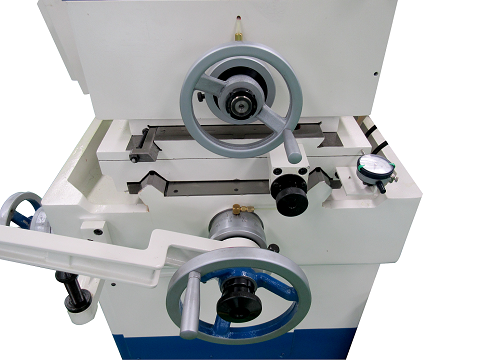

| Hand Wheel |

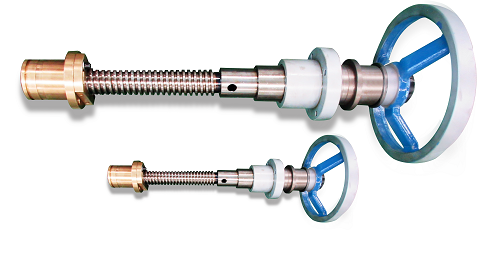

RW feeding hand wheel |

3.5mm/rotation & 0.05mm/graduation | 3.5mm/ratate & 0.05mm/graduation | 3.5mm/rotation & 0.05mm/graduation | 3.5/ratate & 0.05/graduation | 3.5mm/ratate & 0.05mm/graduation | 3.5mm/ratate & 0.05mm/graduation | 4mm/rotation & 0.02mm/ graduation | 3.5mm/rotation & 0.05mm/graduation | 3.5mm/rotation & 0.02mm/ graduation | 3.5mm/rotation & 0.05mm/graduation | 3.5mm/rotation & 0.05mm/graduation | 3.5mm/rotation & 0.05mm/graduation | 3.5mm/rotation & 0.02mm/ graduation | 3.5mm/rotation & 0.05mm/graduation | 3.5mm/rotation & 0.05mm/graduation | / | / | / | / | / | / | / |

RW mirco-feed hand wheel |

0.1mm/rotation & 0.001/graduation | 0.1mm/ratate & 0.001mm/graduation | 0.1mm/rotation & 0.001/graduation | 0.1/ratate & 0.001/graduation | 0.1mm/ratate & 0.001/graduation | 0.1mm/ratate & 0.001/graduation | / | / | / | 0.1mm/rotation & 0.001/graduation | 0.1mm/rotation & 0.001/graduation | 0.1mm/rotation & 0.001/graduation | / | 0.1mm/rotation & 0.001/graduation | 0.1mm/rotation & 0.001/graduation | / | / | / | / | / | / | / |

Bottom slide feeding hand wheel |

9mm/rotation & 0.10mm/graduation | 9mm/ratate & 0.10mm/graduation | 9mm/rotation & 0.10mm/graduation | 9/ratate & 0.10/graduation | 9mm/ratate & 0.10mm/graduation | 9mm/ratate & 0.10mm/graduation | 7mm/rotation & 0.05mm/ graduation | 7mm per rotation 0.02mm per graduation | 7mm/rotation & 0.05mm/ graduation | / | / | / | 7mm/rotation & 0.05mm/ graduation | / | / | / | / | / | / | / | / | / |

Bottom slide micro-feed hand wheel |

0.2mm/rotation & 0.001mm/graduation | 0.2mm/ratate & 0.001mm/graduation | 0.2mm/rotation & 0.001mm/graduation | 0.2/ratate & 0.001/graduation | 0.2mm/ratate & 0.001mm/graduation | 0.2mm/ratate & 0.001mm/graduation | 0.2mm/rotation & 0.001mm/ graduation | 0.2mm per rotation 0.001 per graduation | / | / | / | / | 0.2mm/rotation & 0.001mm/ graduation | / | / | / | / | / | / | / | / | / |

Dressing feeding hand wheel |

2mm/rotation & 0.01mm/graduation | 2mm/ratate & 0.01mm/graduation | 2mm/rotation & 0.01mm/graduation | 2/ratate & 0.01/graduation | 2mm/ratate & 0.01mm/graduation | 2mm/ratate & 0.01mm/graduation | 1.25mm/rotation & 0.01mm/ graduation | 1.25mm per rotation 0.01mm per gradution | 1.5mm/rotation & 0.01mm/ graduation | 2mm/rotation & 0.01mm/graduation | 2mm/rotation & 0.01mm/graduation | / | 1.5mm/rotation & 0.01mm/ graduation | 2mm/rotation & 0.01mm/graduation | 2mm/rotation & 0.01mm/graduation | / | / | / | / | / | / | / |

| NC Units |

Bottom slide drive motor |

/ | / | / | / | / | / | / | / | 1KW AC200V/50Hz | 1.5KW AC220V/50Hz | 1.5KW AC220V/50Hz | 1.5KW AC220V/50Hz | / | 1.5KW AC220V/50Hz | 1.5KW AC220V/50Hz | 1.5KW AC200V/50Hz | 1.5KW AC200V/50Hz | 1.5KW AC200V/50Hz | 1.5KW AC200V/50Hz | 2KW AC220V/50Hz | 1KW AC200V/50Hz | 1KW AC200V/50Hz |

Bottom slide feeding precision(Y1) |

/ | / | / | / | / | / | / | / | 0.001mm | 0.001mm | 0.001mm | 0.001mm | / | 0.001mm | 0.001mm | 0.001mm | 0.001mm | 0.001mm | 0.001mm | 0.001mm | 0.001mm | 0.001mm |

GW dressing motor X1,Z1 |

/ | / | / | / | / | / | / | / | / | / | / | / | / | / | / | 0.4KW AV200V/50Hz 0.75KW AC200V/50Hz | 0.4KW AV200V/50Hz 0.75KW AC200V/50Hz | 0.4KW AV200V/50Hz 0.75KW AC200V/50Hz | 0.4KW AV200V/50Hz 0.75KW AC200V/50Hz | 0.4KW AV200V/50Hz 0.75KW AC200V/50Hz | 0.4KW AV200V/50Hz 0.75KW AC200V/50Hz | 0.4KW AV200V/50Hz 0.75KW AC200V/50Hz |

RW dressing motor X1,Z1 |

/ | / | / | / | / | / | / | / | / | / | / | / | / | / | / | 0.4KW AC200V/50Hz 0.75kW AC200V/50Hz | 0.4KW AC200V/50Hz 0.75kW AC200V/50Hz | 0.4KW AC200V/50Hz 0.75kW AC200V/50Hz | 0.4KW AC200V/50Hz 0.75kW AC200V/50Hz | 0.4KW AC200V/50Hz 0.75kW AC200V/50Hz | 0.4KW AV200V/50Hz 0.75KW AC200V/50Hz | 0.4KW AC200V/50Hz 0.75kW AC200V/50Hz |

Auto loading&unloading mechanical arms motor(B1,B2) |

/ | / | / | / | / | / | / | / | / | / | / | / | / | / | / | 0.4KW AC200V/50Hz 0.4kW AC200V/50Hz | 0.4KW AC200V/50Hz 0.4kW AC200V/50Hz | 0.4KW AC200V/50Hz 0.4kW AC200V/50Hz | 0.4KW AC200V/50Hz 0.4kW AC200V/50Hz | 0.4KW AC200V/50Hz 0.4kW AC200V/50Hz | 0.4KW AC200V/50Hz 0.4kW AC200V/50Hz | 0.4KW AC200V/50Hz 0.4kW AC200V/50Hz |

Auto loading%unloading mechanical feeding precision(B1,B2) |

/ | / | / | / | / | / | / | / | / | / | / | / | / | / | / | 0.02mm | 0.02mm | 0.02mm | 0.02mm | 0.02mm | 0.02mm | 0.02mm |

| Drive motor |

Oil system motor |

2HP(0.7KW) AC380/50Hz | 2HP(1.5KW) AC380/50Hz | 1HP(0.75KW) AC380/50Hz | 1HP(0.75KW) AC380/50Hz | 2HP(1.5KW) AC380/50Hz | 2HP(1.5KW) AC380/50Hz | 2HP(1.5KW) AC380V/50Hz | 2HP(1.5KW) AC380/50Hz | 1HP(0.75KW) AC380V/50Hz | 1HP(0.75KW) AC380/50Hz | 1HP(0.75KW) AC380/50Hz | 2HP(1.5KW) AC380/50Hz | 1HP(0.75KW) AC380V/50Hz | 2HP(1.5KW) AC380/50Hz | 1HP(0.75KW) AC380/50Hz | 2HP(1.5KW) AC380/50Hz | 1HP(0.75KW) AC380/50Hz | 1HP(0.75KW) AC380/50Hz | 2HP(1.5KW) AC380/50Hz | 2HP(1.5KW) AC380/50Hz | 1HP(0.75KW) AC380V/50Hz | 1HP(0.75KW) AC380V/50Hz |

Cooling device drive motor |

1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/5HP(120W) AC380V/50Hz | 2HP(1.5KW) AC380/50Hz | 1/4HP(90W) AC380V/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(90W) AC380V/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/4HP(180W) AC380/50Hz | 1/8HP(90W) AC380V/50Hz | 1/4HP(90W) AC380V/50Hz |

| Capacity |

Machine size |

2350×1960×1550mm | 2350×1960×1550mm | 2350×1960×1550mm | 2350×1960×1550mm | 2350×1960×1550mm | 2350×1960×1550mm | 1800×1400×1450mm | 1500*2600*1850mm | 1800×1400×1450mm | 2350×1960×1550mm | 2350×1960×1550mm | 2350×1960×1550mm | 1800×1400×1450mm | 2350×1960×1550mm | 2350×1960×1550mm | 2350×1960×1550mm | 2350×1960×1550mm | 2350×1960×1550mm | 2350×1960×1550mm | 2350×1960×1550mm | 1800×1400×1450mm | 1800×1400×1450mm |

Machine package size |

2400×2000×1800mm | 2400×2000×1800mm | 2400×2000×1800mm | 2400×2000×1800mm | 2400×2000×1800mm | 2400×2000×1800mm | 2000×1700×1700mm | 2000*3300*2000mm | 2000×1700×1700mm | 2400×2000×1800mm | 2400×2000×1800mm | 2400×2000×1800mm | 2000×1700×1700mm | 2400×2000×1800mm | 2400×2000×1800mm | 2400×2000×1800mm | 2400×2000×1800mm | 2400×2000×1800mm | 2400×2000×1800mm | 2400×2000×1800mm | 2000×1700×1700mm | 2000×1700×1700mm |

Net weight |

2950 kgs | 2850 kgs | 2950 kgs | 3050 kgs | 2950 kgs | 3050 kgs | 1850 kgs | 3185kgs | 1770 kgs | 2950 kgs | 3050 kgs | 2850 kgs | 1770 kgs | 3050 kgs | 2850 kgs | 2850 kgs | 2850 kgs | 2850 kgs | 2950 kgs | 3050 kgs | 1770 kgs | 1770 kgs |

Gross weight |

3150 kgs | 3005 kgs | 3150 kgs | 3250 kgs | 3150 kgs | 3250 kgs | 2000 kgs | 3321kgs | 1920 kgs | 3150 kgs | 3250 kgs | 3005 kgs | 1920 kgs | 3250 kgs | 3005 kgs | 3005 kgs | 3005 kgs | 3005 kgs | 3150 kgs | 3250 kgs | 1920 kgs | 1920 kgs |